Key Highlights

- From traditional methods to modern automation, the journey of beverage production showcases remarkable advancements.

- This article explores the intricate stages involved in transforming a beverage concept into a market-ready product.

- We’ll delve into aspects like formulation, quality control, packaging, and the role of sustainability.

- Understanding these elements provides valuable insights into the complexities of the beverage manufacturing world.

Introduction

The beverage industry has always been a dynamic landscape, driven by ever-evolving consumer interest and technological innovation. Behind every sip of our favorite drinks lies a complex manufacturing process that transforms raw ingredients into refreshing and enjoyable beverages.

This journey, from concept to consumer, involves a series of carefully planned steps that ensure both quality and consistency.

The Evolution of Beverage Manufacturing in the United States

The history of beverage manufacturing in the United States is a testament to ingenuity and adaptation. Early methods were often rudimentary, characterized by manual labor and localized production. As demand grew and technology advanced, the industry witnessed a seismic shift.

The introduction of automation, improved packaging techniques, and sophisticated quality control measures revolutionized beverage production. What was once a largely localized industry transformed into a global behemoth capable of delivering a diverse array of beverages to consumers worldwide.

Historical Milestones in Beverage Production

The narrative of beverage production in the United States is punctuated by key historical milestones that have shaped the industry into what we know today. The early 20th century saw a surge in the popularity of soda, driven by advancements in carbonation and bottling technology. This period marked a pivotal shift towards mass-produced and nationally distributed beverages.

Further innovation came with the development of aluminum cans in the mid-20th century. This revolutionized beverage packaging, offering a lightweight, portable, and recyclable alternative to glass bottles. The latter part of the century witnessed the rise of energy drinks and ready-to-drink teas, reflecting changing consumer preferences and lifestyles.

These historical milestones underscore the constant innovation that defines the beverage industry. As technology continues to evolve, we can anticipate further transformations in the way beverages are produced, packaged, and consumed.

Modern Advances in Manufacturing Techniques

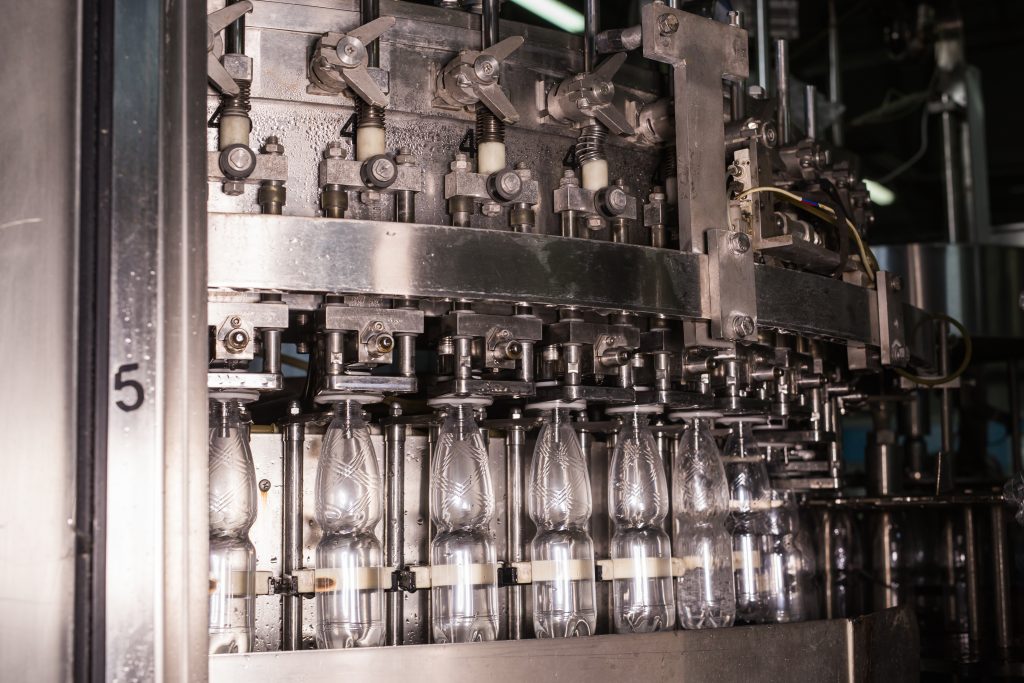

Today, beverage manufacturing involves cutting-edge technology and meticulous processes. Automation plays a central role, and advanced machinery streamlines various stages, from ingredient mixing to bottling and packaging.

Here are some of the key modern advances driving efficiency and flexibility in beverage production:

- High-Speed Bottling and Canning Lines: These automated systems can fill and package thousands of beverages per hour, significantly increasing production capacity.

- Sophisticated Filtration and Purification Systems: Ensuring product safety and quality are paramount. Modern filtration techniques remove impurities and ensure the beverage meets the highest standards.

- Precision Control Systems: Automated systems monitor and adjust parameters like temperature, pressure, and flow rate in real-time, guaranteeing consistency and reducing waste.

These advancements not only optimize production but also enable manufacturers to respond rapidly to evolving consumer preferences and market demands.

Key Stages of the Beverage Production Process

Bringing a new beverage to the market involves a multifaceted process that demands careful planning and execution at every stage. It all begins with an idea—a vision for a new taste sensation or a functional drink that addresses a specific consumer need.

From there, the journey goes through ideation, formulation, rigorous quality checks, packaging, and finally, distribution. Each stage plays a critical role in shaping the final product and ensuring it meets the highest standards of quality and safety.

From Concept to Shelf: Ideation and Formulation

The path from conception to a product on the shelf is a complex journey. It begins with an idea, whether it’s a new, refreshing soda flavor or a health-focused, vitamin-infused beverage. Once the concept is defined, the formulation process commences, marking the stage where the true craftsmanship of beverage creation begins.

Beverage formulation is a delicate balancing act. Flavor profiles are developed and refined, ensuring a harmonious blend of tastes that will entice the consumer. Beyond taste, factors like color, aroma, texture, and consistency all come into play.

Throughout the formulation process, product safety remains paramount. Ingredients are meticulously sourced and tested, and rigorous quality control measures are implemented at every step to ensure the final product meets all regulatory standards.

Quality Assurance and Ingredient Sourcing

Quality assurance is non-negotiable in the beverage industry. From the sourcing of raw materials to the final packaged product, each step must adhere to stringent quality standards. This involves regular testing at various stages of production to monitor factors like taste, color, clarity, and the presence of any contaminants.

Ingredient sourcing plays a pivotal role in both product quality and brand reputation. Many beverage companies are increasingly prioritizing ethical and sustainable sourcing practices, opting for ingredients that are responsibly grown and traded.

| Aspect | Importance |

| Ingredient Traceability | Ensures transparency and accountability within the supply chain, allowing manufacturers to track the origin and journey of each ingredient. |

| Supplier Audits | Regular audits of suppliers guarantee they adhere to ethical and sustainable practices, ensuring the integrity of the supply chain. |

| Sustainable Packaging | Choosing eco-friendly packaging options, such as recycled materials or biodegradable alternatives, minimizes the environmental impact of the product. |

This commitment to transparency and ethical sourcing resonates with environmentally conscious consumers and contributes to a more sustainable and responsible beverage industry.

Cheers!

Understanding the intricate process of beverage manufacturing unveils a world of innovation and evolution. From historical milestones to modern advances, each stage plays a pivotal role in delivering quality beverages to consumers.

The journey from ideation to formulation, coupled with strict quality assurance measures, showcases the dedication of the industry towards excellence. Embracing sustainability practices further solidifies the commitment to environmental stewardship.

If you’re ready to bring your beverage brand ideas to life, reach out to us today for expert manufacturing services. We’re here to help you every step of the way.